TEMP CELL Mechanical-Air Flotation Cells

- Designed for processing of non-ferrous and precious metal ores, apatites, phosphorites, graphites, fluorites and other ore types.

- Leading flotation technology

- Cell volume from 5 m3 to 630 m3

- Symmetrical design

- TEMP FLOW agitation mechanism

- New TEMP DRIVE drive

- Special froth launder structures

- The cylindrical chamber yields excellent results of rougher, scavenger or cleaner flotation and this chamber is nowadays the leader of the flotation technology.

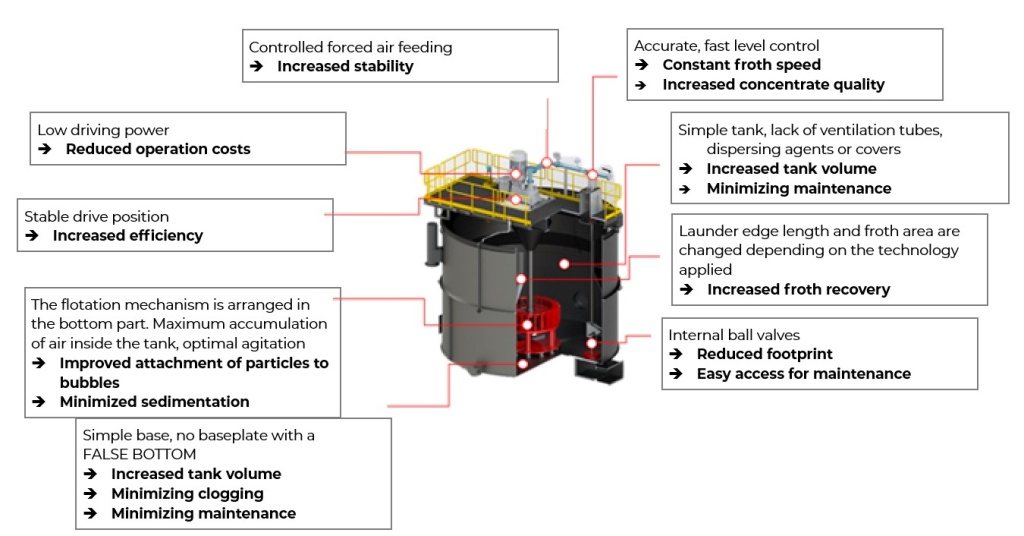

TEMP CELL Advantages

Excellent Agitation and Minimal Volume of Circulating Material

The cylindrical chamber with the TEMP FLOW mechanism operates as an ideal agitator maximizing the amount of contacts between mineral particles and air bubbles and reducing the volume of the circulating volume. The TEMP FLOW flotation agitator improves process parameters, reduces power consumption and operation costs.

The TEMP FLOW mechanism is a standard equipment type for the TEMP CELL flotation cell range. TEMP FLOW is also suitable for upgrading of flotation cells by different manufacturers.

TEMP FLOW mechanism

with a V-belt drive

TEMP FLOW mechanism

with a gear drive

Optimal Aeration and Froth Recovery

TEMP CELL chambers maintain optimal froth surface area based on mineralogy and kinetics. The chambers are designed accounting for maximum carrying load and froth launder load for a specific task.

Reliability and Efficiency

When using large cells, it is important to make each unit of the equipment as much reliable as possible. The deep analysis of hydrodynamics allowed us to design extremely reliable large-size cells which are capable to withstand changes in feed and even oversize material without sedimentation. Mechanical parts are thoroughly sized in order to reduce vibrations and loads and wearing parts are simple and safe in maintenance.

The TEMP DRIVE drive is also designed with consideration of high loads combining simplicity of maintenance, high-class efficiency and compactness of the structure.