Flotation

TEM Partner is a Russian designer and manufacturer of high-tech flotation equipment

Flotation cells by TEM Partner maximize recovery of valuable components from ore.

TEM Partner supplies equipment for the entire flotation cycle including automation systems, pumps, regrind mills, cyclones and other equipment.

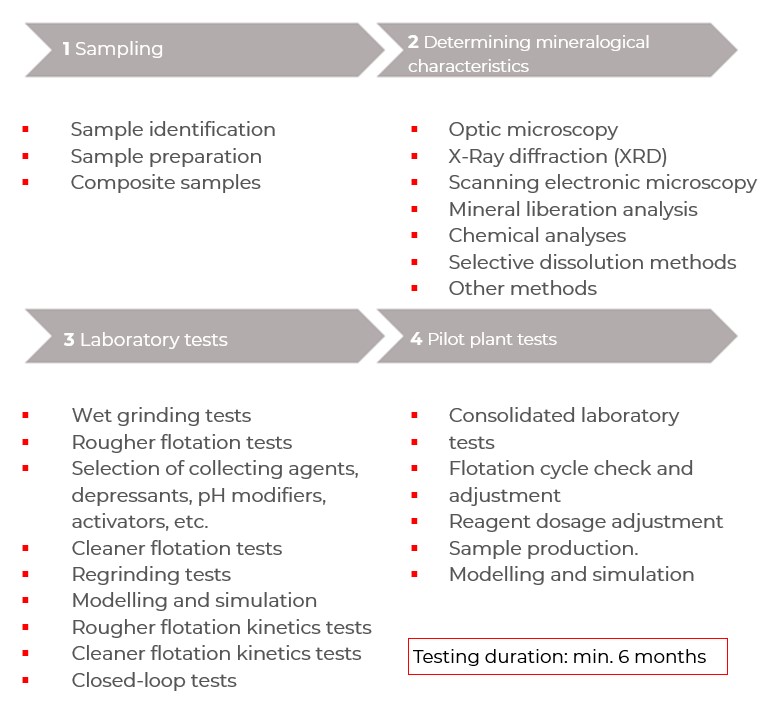

Comprehensive Approach to Selection of Flotation Equipment

Selection of equipment begins with flotation testwork. To clarify process parameters of the studied mineral material, the laboratory flotation testwork is performed on site or in a laboratory.

Flotation Cells for Your Goals

To achieve maximum benefits of processing of different-size particles, we develop unique solutions for each flotation cell. The heart of a cell is the agitator which creates interaction between bubbles and particles and the criterion of its operation is efficient froth recovery.

TEMP FLOW Mechanism

The TEMP FLOW mechanism maximizes the contact between bubbles and particles in the shearing area between the rotor and the stator. High shear forces produce a sufficient amount of energy so that fine particles can penetrate through the surface energy layer carried by air bubbles.

The TEMP FLOW energy-saving mechanism improves process parameters. This mechanism allows to maintain pulp motion without excessive turbulent flows. Large particles contact with air bubbles thanks to intensive and slow mixing, and reduction of the number of particle separations from air bubbles to maximize recovery. TEMP FLOW is used in tank-type mechanical-air machines and flash cells.

Froth Control to Maximize Recovery

Another goal of flotation is keeping the froth in constant motion to provide high recovery and to maximize the quality of the concentrate. TEMP flotation cells are fitted with froth cones maintaining constant froth motion.

Special Launder Structures

High-volume inner launders, central launders or high-volume radial launders provide fast recovery of froth and reduce separation of especially the largest particles.

Cascade Level Control

Periodical and uncontrollable sharp deviations in flotation feed occur quite frequently in actual operation conditions. Cascade level control is used to control previous operations and to transmit compensation signal to the flotation cell controller before the deviations lead to reduction of flotation characteristics.

The cascade level control solution is based on the feed-forward control principles and unique automatic setting functions. This solution may be conveniently integrated in FlotCon panel as a plug-in module and does not require additional measurement modules.

FlotCon Operator Interface

We deliver a unique flotation cell control solution: FlotCon. It is a separated control panel installed on a flotation cell which substitutes conventional field controllers and performs a number of additional functions.

A PLC-based FlotCon station is fitted with an easy-to-use touchpad allowing to obtain control circuit control information, to view trends and to adjust flotation air flow and pulp levels at preset points.

Simple Start at Full Load

A unique-structure rotor with a downward cone provides fast start-up under load after scheduled and off-scheduled shutdowns.